Enhanced Flexible Mold Lifetime for Roll‐to‐Roll Scaled‐Up Manufacturing of Adhesive Complex Microstructures

Bioinspired Microstructured Adhesives with Facile and Fast Switchability for Part Manipulation in Dry and Wet Conditions

Smart Materials for manipulation and actuation of small-scale structures

3D nanofabrication of various materials for advanced multifunctional microrobots

Liquid Crystal Mesophase of Supercooled Liquid Gallium And Eutectic Gallium–Indium

Machine Learning-Based Pull-off and Shear Optimal Adhesive Microstructures

Information entropy to detect order in self-organizing systems

Individual and collective manipulation of multifunctional bimodal droplets in three dimensions

Microrobot collectives with reconfigurable morphologies and functions

Self-organization in heterogeneous and non-reciprocal regime

Biomimetic Emulsion Systems

Giant Unilamellar Vesicles for Designing Cell-like Microrobots

Bioinspired self-assembled colloidal collectives drifting in three dimensions underwater

3D nanofabrication of various materials for advanced multifunctional microrobots

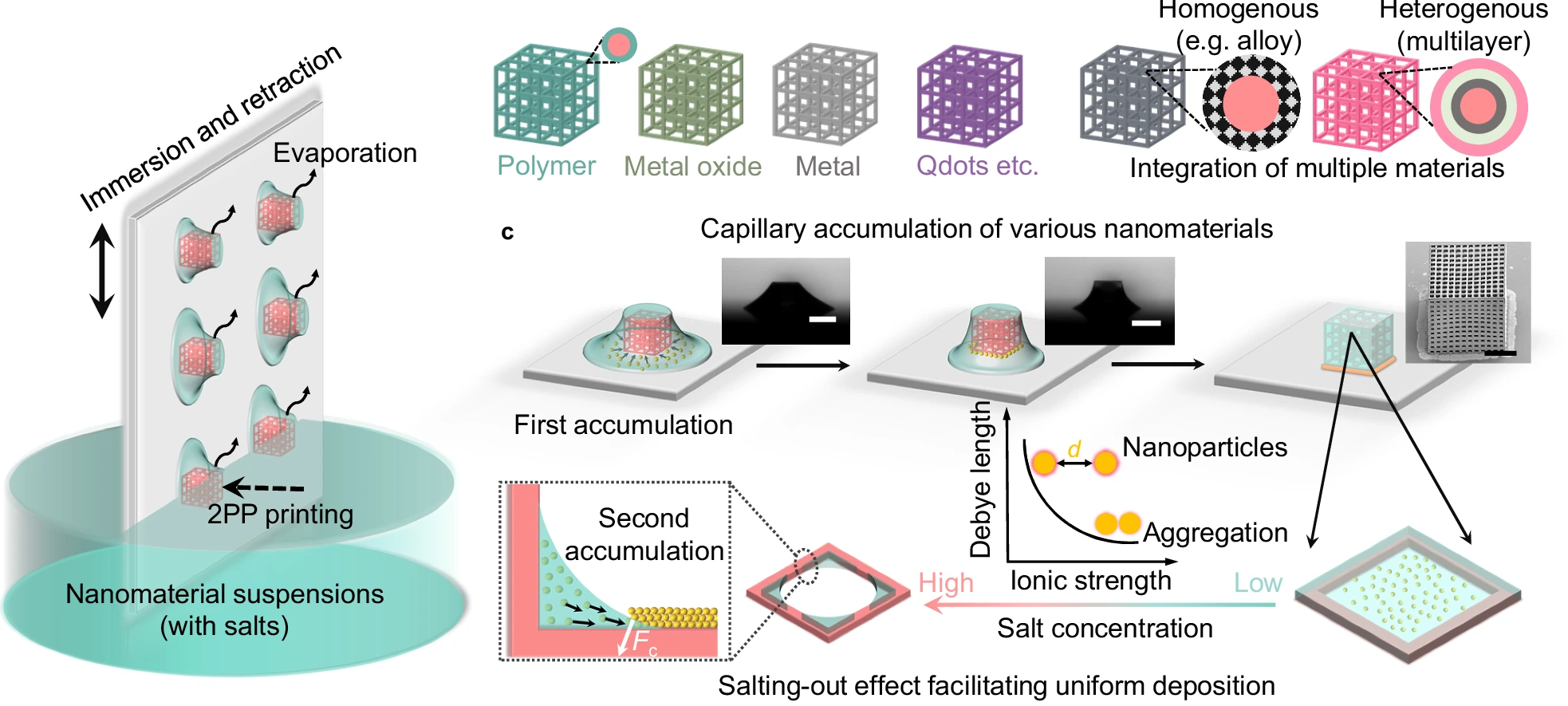

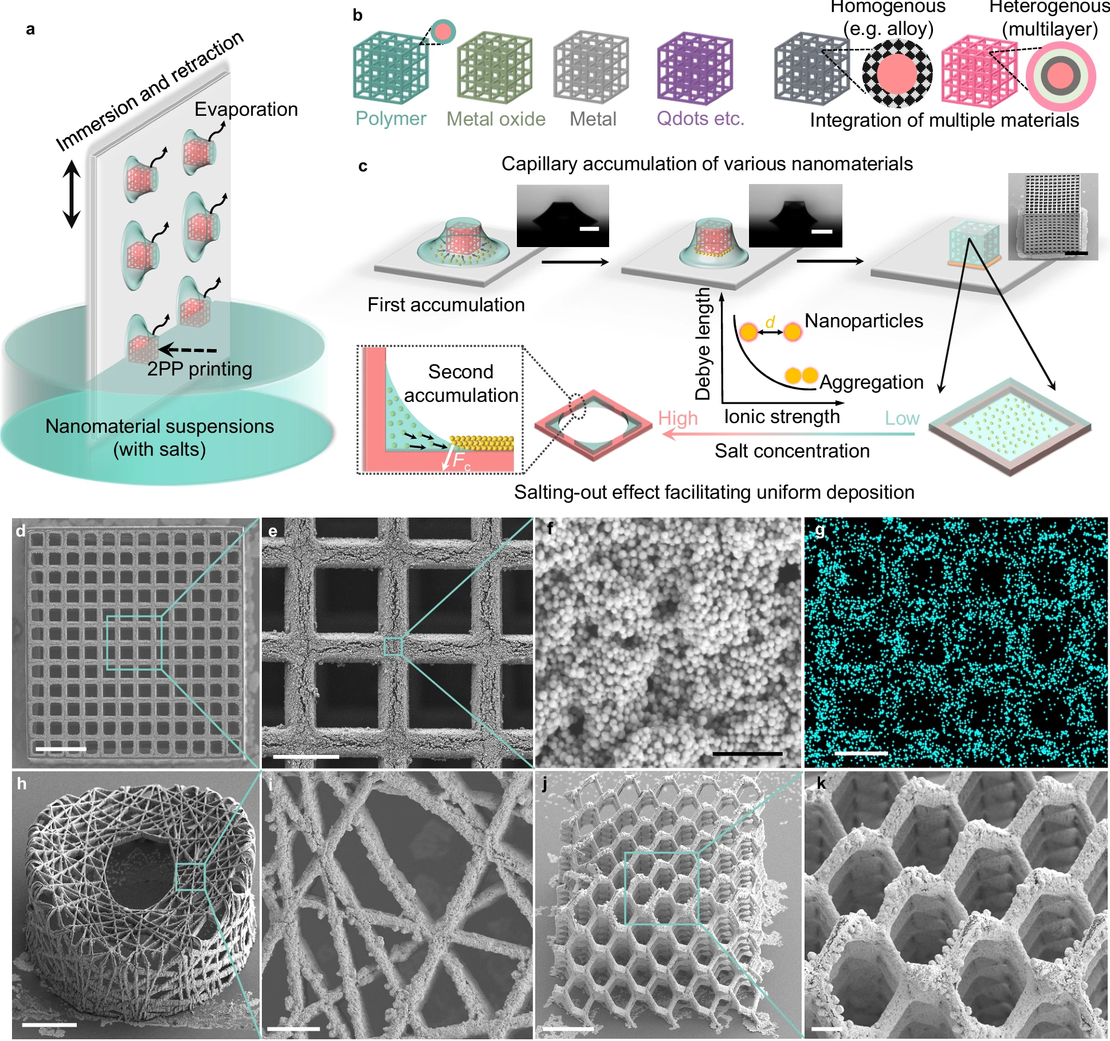

Microrobots are a new kind of smart microdevice that can harvest energy stored in the surrounding environment to perform complicated tasks. Fabricating highly multifunctional microrobots has been the key challenge for realizing applications, such as targeted drug delivery, biosensing, environment remediation, and minimally invasive surgery. Among all the fabricating methods, two-photon polymerization (TPP) capable of printing complex 3D micro/nanostructures using functional materials has been widely used in fabricating microrobots. Two important problems, however, are faced:

a. The materials used in TPP are restricted to polymeric materials, either commercial photoresist or homemade hydrogel, which only show simple functionalities. While other functional non-polymeric materials, such as metal, metal oxide, quantum dots, metal organic framework (MOF), and organic covalent framework (COF), etc. are quite difficult to print.

b. This technology is difficult to integrate multi-functional materials into a single structure to make it multi-functional. Existing printing methods could only integrate a few materials via a special-designed microfluidic component or multiple printing of different precursors, both of which are extremely low efficient.

Therefore, a general 3D nanofabrication technology that could print complex micro/nanostructures with arbitrary materials and integrate different materials into a single structure easily remains a big challenge. This technology would not only be a great breakthrough to fabricate multi-functional microrobots but also significantly promote to fabricate much more multifunctional various microdevices, such as micro-optical devices, micro metamaterials, microelectronics etc. than ever before[].

Members

Publications